Design

assistance

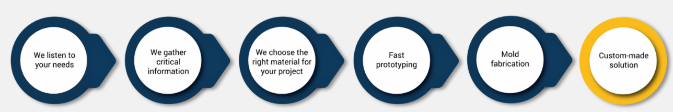

We aim to find innovative solutions that meet your needs while focusing on the efficiency of our manufacturing processes for the optimum production of your parts.

Our approach

- Critical information and risk analysis

- Choice of material

- 3D printing prototyping

Mold

fabrication

We design and manufacture our own molds, which greatly improves the delivery time of new part prototypes.

Our team will help you design your part and the mold required to produce it. Our experts will offer different options regarding the mold format and suggest the most flexible mold concept possible to allow for any change to the piece’s shape. The performance of your part is our primary concern.

Rubber parts

molding

For over 34 years, experts from BCI Rubber continue to perfect the art of moulding custom rubber parts in order to provide you with a product that meets all your needs. The elastic properties of rubber make the ideal choice for, among other things, absorbing shock and vibration or to seal.

Our 36 presses, ranging from 30 to 1500 tons capacity, allowing us to produce small and large-scale parts.

Capacity

- Maximum dimensions: 130” (1 300 mm) length x 52” (1 322 mm) width

- Weight: from a few grams

to 1 000 kg

Silicone part

molding

BCI Rubber offers a complete solution for silicone part molding. Thanks to their heat resistance and flexibility, silicone parts are often used in specialized fields such as food, medical and electrical.

Metal-polymer

assembly

We have developed expertise and innovative techniques to ensure a strong adhesion between metal, rubber, ceramic and silicone. The result is an endless possibility of combinations that could apply to all areas.

CNC & Conventional

Machining

Our cutting-edge digital and conventional machining equipment, combined with our experienced machinists, allow us to offer a turnkey service from parts design to delivery.

Equipment & Services

- Multi-axis CNC lathe turning

- Horizontal CNC milling

- Vertical CNC milling

- A complete range of machine tools (milling machines, lathes, saws)

- Heat treatment

- Just-in-Time or Kanban manufacturing

- Primary part and subassembly machining

- Quality assurance (inspection record, aspect ratio, mill test)